Why Stix™?

At NewWave, we're pioneers of the original ultra clean stick machine in the UK . With over 50 years experience in the packaging industry, we're proud to announce the latest innovation in Aseptic technology in the form of our multi-lane single serve packaging solution – A Stix™.

Technology

The patented technology combines flexible packaging with an aseptic filling in a single serve portion size that is suitable for dairy, food and beverages as well as nutraceuticals and other volatile liquids. The machine produces 900 packs per minute to maximise operational efficiency and to ensure optimum output for the line.

Packaging

Flexible packaging is fast becoming the most popular form of packaging, particularly within fast moving consumer goods such as the food and beverage category. Businesses are favouring it over the traditional rigid packaging due to benefits such as ease of transport, cost efficiency and consumer needs. More environmentally friendly than the existing single serve format (the cup), the Stix™ format uses a single material which gives superior sealing, uses end-to-end material and increases shelf-life due to the sterile filling and barrier qualities of our specially designed film. Live in a hot or humid climate? We have a film for you. With a choice of laminates and further reduced O₂ and H₂O transfer rates, you can ensure your product stays fresher for longer without the need for refrigeration.

Design

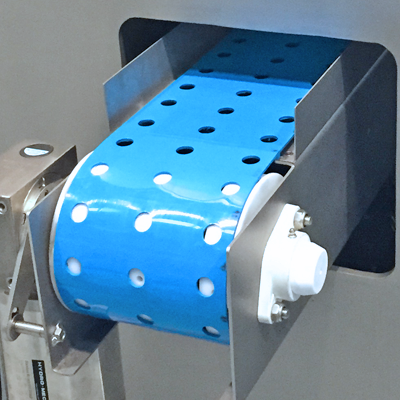

The Stix™ design has been crafted for the perfect pour, with an easy to tear nick that creates an ingenious spout for precision pouring of the liquid. Unlike the awkward cup design that can spurt when the lid is peeled back, Stix™ are easy to use with minimal spillage.

Want to switch to Stix™?

Get in touchStix™ Vs Cups

The single serve liquid market has been dominated by the cup/thimble/jigger format for the last 40 years, with little innovation in the sector…until now.

With so many great benefits, including cost efficiency, positive environmental impact and bringing a new innovative packaging format and extended shelf-life to your customers, it’s a no-brainer for your product!

| Cups | Stix™ | |

|---|---|---|

Environment | Weight of cup = 0.78 gram | Weight of Stix™ is 0.36 grams = significant reduction in packaging material |

Wastage of material cut around the circular cup | Straight format of the Stix™ allows end to end usage of the film with minimal wastage | |

2 types of material (lid and cup) required | 1 type of material used. | |

Wastage | Difficult sealing process with wastage | Single material sealing – minimal wastage |

Rigid nature of cup leads to spoilage within retail packs. This can be as much as 35% wastage | Flexible nature = no piercing of product and no leakers | |

Old technology and therefore less efficient | New and highly efficient operational design | |

Shelf Life | Additives/preservatives needed | No additives/preservatives needed |

3-6 months (dairy/non-dairy) | 6-12 months (dairy/non-dairy) | |

Cost Savings | Non-flexible nature of cup = wasted space in box | 50% more product in one box Vs cups |

Storage requirements higher | 50% reduced storage requirements p/unit | |

Distribution costs higher due to pack size | Reduced box sizes = Distribution savings | |

Some refrigeration required | No refrigeration required |

Want to switch to Stix™?

Get in touchEnvironment

NewWave Packaging is a young, innovative packaging technology business that develops machinery for flexible single serve packaging. Our solutions are suitable for liquids, foods and beverages and other unstable liquids that require aseptic processing. Furthermore, our machines are built to FDA specifications which enables us to develop solutions appropriate to global markets.

Our patent pending machinery allows other businesses to reduce their impact on the environment by using more efficient technology, with minimal production wastage and zero spoilt product due to leakage. Based in the industrial hub of South Wales, we benefit from excellent links to both local and international transport networks. Our company’s greatest asset is our pool of dedicated and talented staff, who bring with them decades of industry experience.

Our key areas of improvement focus on minimising and managing our waste, saving energy and improving our business travel and haulage impacts. Specifically we work to:

- Reduce all waste streams by working with our engineers, suppliers, clients & employees;

- Recycle and divert from landfill as much as possible of the residual waste;

- Review all areas of the business to identify ways in which we can reduce our energy consumption; including increased use of low; energy lighting, smart controls for heating, lighting and ventilation and the installation of renewable energy systems;

- Where possible, we car pool and utilise video conferencing and other remote working solutions; and

- Priorities using aviation, shipping and haulage companies at the forefront of good environmental practice.