Our Technology

We have developed a unique and patent-pending protected design that has transformed the liquid, long life and single serve aseptic portion market. It is available for licence across different industry sectors and regional territories.

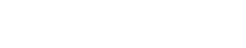

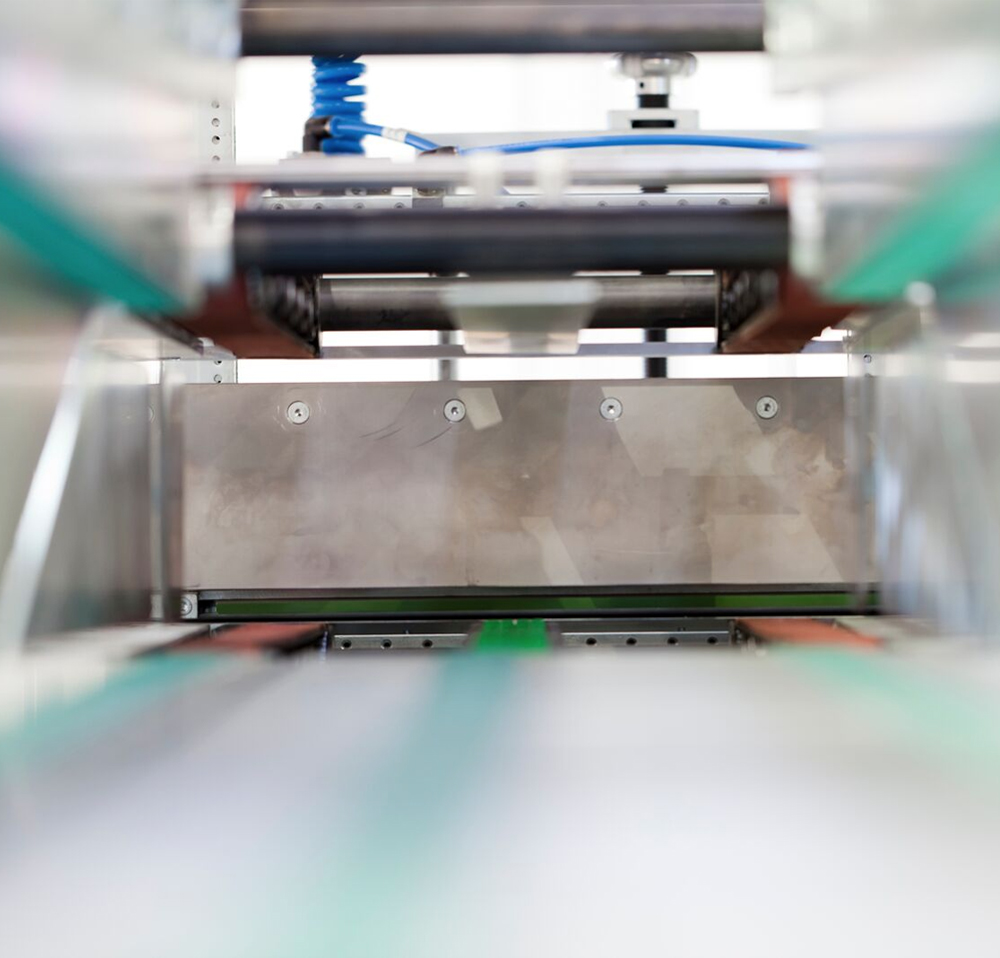

It is the largest, multi-lane vertical form, fill and seal aseptic packaging line in the world. The system has a precisely maintained environment and state-of-the-art precision engineering which incorporates hygienic welding and the highest quality polished metallic finish to ensure an exact aseptic filling that has never been seen before.

The intermittent motion is controlled by a bespoke integrated Siemen’s PLC control system. Our R+D team develop and design new products and upgrades for ultimate product versatility. A full manufacture/production audit trail is available for all lines.

Want to find out more?

Get in touchQuality Standards

We work to British Quality and Environmental standards BS8555. All machines are made to the highest quality standards, built within the 3As and Good Machine Building practise and are CE certified. They are also built to the USAs Food and Drug Administration aseptic specifications.

It's our policy that our customer's requirements are fully and completely satisfied in an effective, efficient and safe manner throughout all stages of engagement.

To assist in achieving this policy, we have developed a management system that covers all areas of the company's activities. This system is based on good working practises and complies with the requirements of ISO9001:2008, and all relevant statutory, regulatory and contractual requirements.

The system has been implemented using a combination of competent personnel.

The system is continuously reviewed to ensure that it's effective and applicable to our organisation.